High Quality Service

We are a professional manufacturer of industrial robot arms, we provide high-quality, high-performance, high-reliability products, and also attach great importance to service, the following are a few highlights of our service:

1) Professional team: We have a professional team, including engineers and technicians, who have rich experience and skills in the design, production and maintenance of robot arms.

2) Quick response: We promise to respond quickly to customers' problems and provide the best solutions in a timely manner to ensure that customer needs are met in a timely manner.

3) Personalized customization: We can provide personalized customized services according to customer needs to meet different application needs of customers.

4) After-sales service: We provide perfect after-sales service, including the installation, commissioning, maintenance and upgrading of robot arms, to ensure that customers can receive long-term support and services.

Our goal is to be a leading manufacturer in the industry, providing high-quality robotic arms and excellent customer service, and we look forward to working with you to create a better future together.

1) Professional team: We have a professional team, including engineers and technicians, who have rich experience and skills in the design, production and maintenance of robot arms.

2) Quick response: We promise to respond quickly to customers' problems and provide the best solutions in a timely manner to ensure that customer needs are met in a timely manner.

3) Personalized customization: We can provide personalized customized services according to customer needs to meet different application needs of customers.

4) After-sales service: We provide perfect after-sales service, including the installation, commissioning, maintenance and upgrading of robot arms, to ensure that customers can receive long-term support and services.

Our goal is to be a leading manufacturer in the industry, providing high-quality robotic arms and excellent customer service, and we look forward to working with you to create a better future together.

User Benefits

1.Improve production efficiency: Using our CNC system and industrial robot arm can greatly improve production efficiency. Our CNC controller has the characteristics of high speed and high precision, and can quickly complete a variety of complex machining tasks. Our robotic arms can replace manual completion of dangerous or boring tasks, greatly improving life.

2.Reduce production costs: By using our CNC system and industrial robot arm, customers can reduce labor costs and reduce production costs. Our robot arm can work 24 hours a day without the need for rest and sleep, avoiding the waste of human resources and work.

3.Improve production quality: Our CNC system and industrial robot arm have the characteristics of high precision and high stability, which can ensure the consistency and quality of products. Our robot arm adopts advanced control technology to complete a variety of tasks with precision, avoiding errors and instability that may occur in manual operation.

4.Improved safety: Our robot arm can complete some dangerous operations, avoiding safety hazards that workers may encounter. Our CNC systems and industrial robot arms can also avoid injuries and accidents that may occur in manual operation.

2.Reduce production costs: By using our CNC system and industrial robot arm, customers can reduce labor costs and reduce production costs. Our robot arm can work 24 hours a day without the need for rest and sleep, avoiding the waste of human resources and work.

3.Improve production quality: Our CNC system and industrial robot arm have the characteristics of high precision and high stability, which can ensure the consistency and quality of products. Our robot arm adopts advanced control technology to complete a variety of tasks with precision, avoiding errors and instability that may occur in manual operation.

4.Improved safety: Our robot arm can complete some dangerous operations, avoiding safety hazards that workers may encounter. Our CNC systems and industrial robot arms can also avoid injuries and accidents that may occur in manual operation.

Product Quality And Reliability

As a professional manufacturer of CNC systems and industrial robot arms, we understand the importance of product quality and reliability to our customers.

First of all, we use the most advanced technology and processes, and all products are designed and manufactured in accordance with international standards to ensure the quality and reliability of the products. Our CNC controller supports ATC+PLC+MACRO function, which can meet the diverse production needs of customers. And our robot arm has many types, including welding robots, handling robots, spraying robots, etc., which can meet the different production needs of customers.

Secondly, we strictly control every link of the product, from the selection of raw materials, production process, assembly process, to strict product testing and packaging, we have carried out continuous control. Each of our products undergoes rigorous technical testing to ensure the highest level of quality and reliability. Before shipment, we will strictly pack each order to ensure that the product will not suffer any damage during transportation.

Finally, we have been adhering to the concept of "customer first, quality first", and constantly strive to improve product quality and reliability. We provide professional after-sales service and technical support to provide customers with comprehensive solutions to ensure that customers are carefree in the process of using our products.

In summary, our CNC system and industrial robot arm have excellent quality and reliability, and are well received by customers. If you are looking for high-quality, reliable CNC systems and robotic arms, we look forward to working with you.

First of all, we use the most advanced technology and processes, and all products are designed and manufactured in accordance with international standards to ensure the quality and reliability of the products. Our CNC controller supports ATC+PLC+MACRO function, which can meet the diverse production needs of customers. And our robot arm has many types, including welding robots, handling robots, spraying robots, etc., which can meet the different production needs of customers.

Secondly, we strictly control every link of the product, from the selection of raw materials, production process, assembly process, to strict product testing and packaging, we have carried out continuous control. Each of our products undergoes rigorous technical testing to ensure the highest level of quality and reliability. Before shipment, we will strictly pack each order to ensure that the product will not suffer any damage during transportation.

Finally, we have been adhering to the concept of "customer first, quality first", and constantly strive to improve product quality and reliability. We provide professional after-sales service and technical support to provide customers with comprehensive solutions to ensure that customers are carefree in the process of using our products.

In summary, our CNC system and industrial robot arm have excellent quality and reliability, and are well received by customers. If you are looking for high-quality, reliable CNC systems and robotic arms, we look forward to working with you.

Competitive Advantages

1) Leading technology: We have a strong R & D team and technical personnel, constantly introduce new products and technologies, and actively participate in domestic and foreign industry exhibitions and exchange activities to maintain a leading position in technology.

2) Rich product line: Our CNC system and industrial robot arm cover a variety of fields, including welding, handling, spraying, etc., which can meet the different needs of customers.

3) Quality products: We pay attention to the quality and reliability of products, and all products will undergo strict technical testing and quality inspection before leaving the factory to ensure that product quality meets customer needs.

4) Efficient customer service: We have established a perfect after-sales service system, including product installation and commissioning, training and maintenance services to ensure the after-sales service experience of customers.

2) Rich product line: Our CNC system and industrial robot arm cover a variety of fields, including welding, handling, spraying, etc., which can meet the different needs of customers.

3) Quality products: We pay attention to the quality and reliability of products, and all products will undergo strict technical testing and quality inspection before leaving the factory to ensure that product quality meets customer needs.

4) Efficient customer service: We have established a perfect after-sales service system, including product installation and commissioning, training and maintenance services to ensure the after-sales service experience of customers.

Product Center

We have established long-term cooperative relations with many enterprises.

Product Application

Warmly welcome friends from all walks of life to visit, investigate and negotiate business!

About Us

Shenzhen Guanhong Technology Co.,Ltd.

SZGHTECH Group is a leading China manufacturer of CNC systems, industrial robots, and automated CNC machines, operating a 20,000㎡ modern factory with 300+ staff and 100+ R&D engineers. We independently develop and produce CNC controllers, servo drives, motors, robots, CNC lathes, milling machines, machining centers, and full CNC kits. With full in-house control of mechanical design, hardware development, motion-control algorithms, software platforms, precision assembly and strict quality testing, we deliver 30,000+ CNC systems, 5,000+ robots and 2,000+ CNC automation machines annually. Supported by CNC and robotics labs, an automation R&D center, and advanced testing platforms, SZGHTECH provides customized solutions for metalworking, welding, coating, handling, packaging and OEM/ODM projects, serving customers in 126+ countries. We are committed to becoming a global leader in CNC and robotic intelligent manufacturing systems. Driven by technological innovation, we work hand in hand with global customers to create an efficient, intelligent, and sustainable automated future, continuously empowering the digital transformation of CNC and robotics.

-

+

Factory land occupation

-

+

Senior technical engineer

-

+

Utility model patent

-

+

Global customers

Video Center

Warmly welcome friends from all walks of life to visit, investigate and negotiate business!

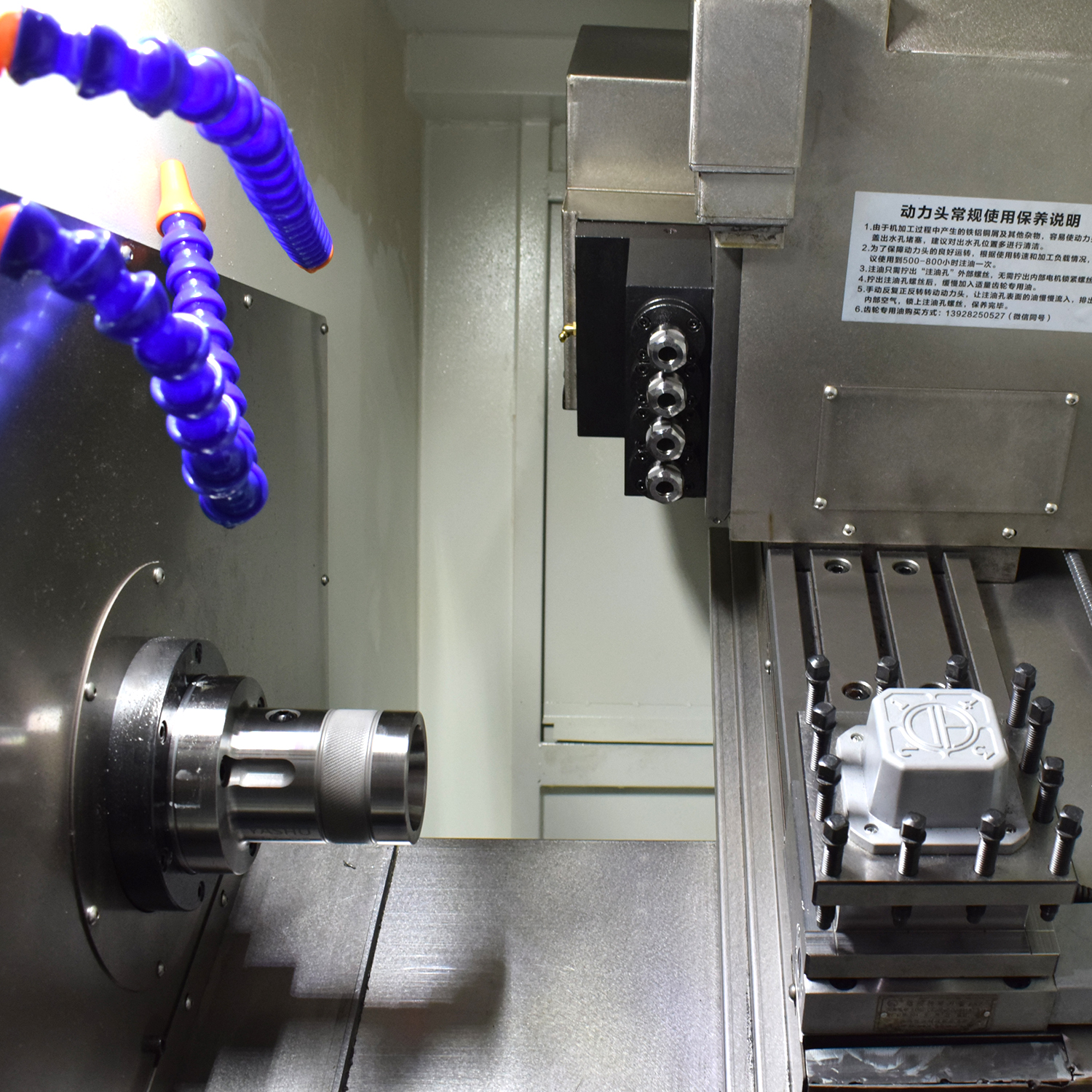

SZGH-46Y Turning and Milling Composite Machining Center

SZGH T1600 10C General-Purpose Robot Demonstration

SZGH-650 Milling Machine: Demonstration of surface milling, drilling, and tapping operations

SZGH 650 milling machine for processing round materials.

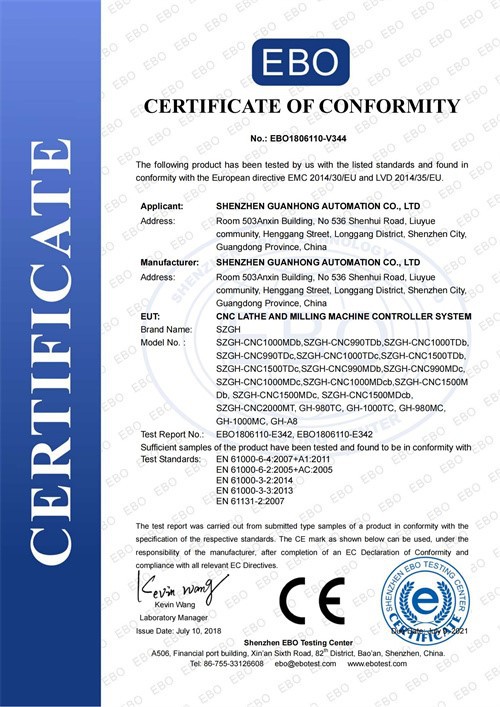

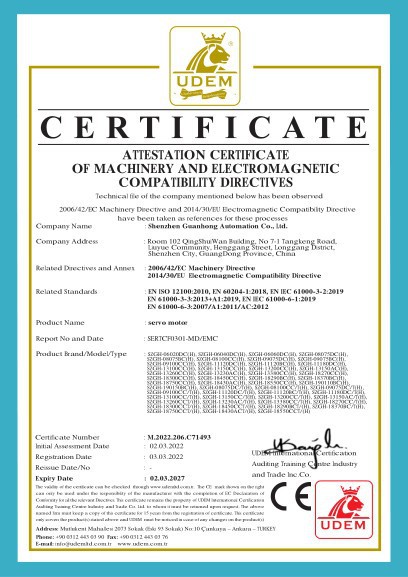

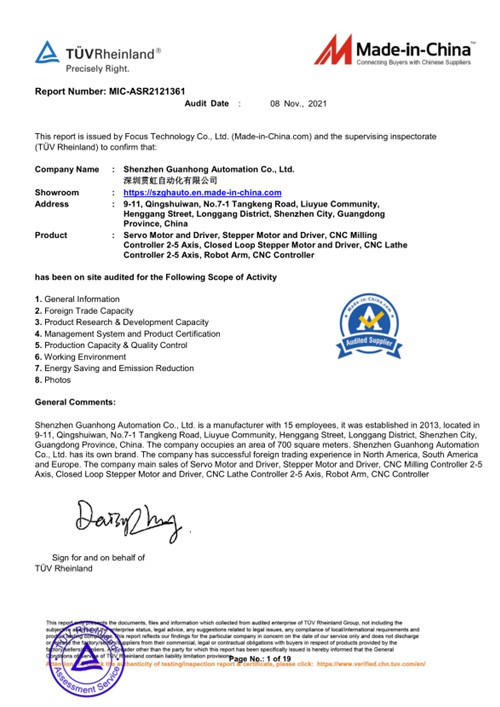

Quality · Certification · Export-Ready Compliance

SZGHTECH runs a full-scale 20,000 ㎡ factory where all operations — from in-house R&D, servo & motion-control development, CNC controller and robot production, to final quality inspection — are strictly managed under one roof. We hold recognized factory-level certifications from Bureau Veritas (BV) and SGS (Gold Plus Supplier Assessment), ensuring our manufacturing, QC, and export processes meet rigorous global standards. Our machines are CE-marked, fully compliant with EU safety, electrical, and environmental regulations — ready for lawful sale and operation across Europe and the entire EEA.

As a direct manufacturer (not a trading agent), SZGHTECH provides complete documentation — technical files, CE declarations, export-ready paperwork, user manuals — along with traceable production records and export-ready CNC & robotic automation systems.

Choosing SZGHTECH means partnering with a globally certified, export-ready manufacturer, delivering high-precision, compliant automation solutions — ready for installation and reliable operation anywhere in the world.

News Center

Official certification, professional after sales service.

Gratitude for the Journey, Creating the Future Together

2025 is drawing to a close. Looking back on this year, for SZGH, it has been a year full of challenges, but also a year of continuous breakthroughs, gaining trust and friendship. At this year-end, with a grateful heart, we extend our most sincere thanks to all customers, partners, and friends who have supported and trusted SZGH.

Small Slant Bed CNC Lathes Empower Modern Precision Manufacturing Across Global Industries

As global manufacturing continues to evolve toward higher precision, automation, and intelligent production, small slant bed CNC lathes have become an essential foundation for modern machining workshops. Known for their compact structure, high rigidity, excellent chip evacuation, and outstanding machining accuracy, slant bed CNC lathes are widely adopted across multiple industries that demand reliability, efficiency, and consistent quality. At SZGH, we have been focusing on the development and manufacturing of advanced CNC machine tools, providing customers worldwide with stable and efficient slant bed CNC lathe solutions.

Shenzhen Guanhong Technology Co., Ltd.(SZGH) is thrilled to announce an exciting milestone in our global expansion journey—the official appointment of a dedicated and highly trusted distributor in Pakistan for our CNC controller product line. This achievement not only marks a new chapter in SZGH’s international development but also strengthens our commitment to bringing advanced, reliable, and cost-effective CNC control technologies to customers around the world.

In November 2025,SZGH assembled an elite team composed of senior CNC automation engineers and CNC machine tool application experts,embarking on a two-week in-depth client visit and CNC technical service journey to Iran and Turkey. This trip covered several important industrial cities. SZGH's CNC automation team not only engaged in in-depth exchanges with existing clients but also effectively solved various problems and challenges encountered by clients in production through professional CNC technical support.