Company Overview

SZGHTECH Group is a leading China manufacturer of CNC systems, industrial robots, and automated CNC machines, operating a 20,000㎡ modern factory with 300+ staff and 100+ R&D engineers.

We independently develop and produce CNC controllers, servo drives, motors, robots, CNC lathes, milling machines, machining centers, and full CNC kits. With complete in-house control of mechanical design, hardware development, motion-control algorithms, software platforms, precision assembly, and strict quality testing, we deliver 30,000+ CNC systems, 5,000+ robots, and 2,000+ CNC automation machines annually.

Supported by CNC and robotics laboratories, an automation R&D center, and advanced testing platforms, SZGHTECH provides customized solutions for metalworking, welding, coating, handling, packaging, and OEM/ODM projects, serving customers in 126+ countries. We are committed to becoming a global leader in CNC and robotic intelligent manufacturing systems.

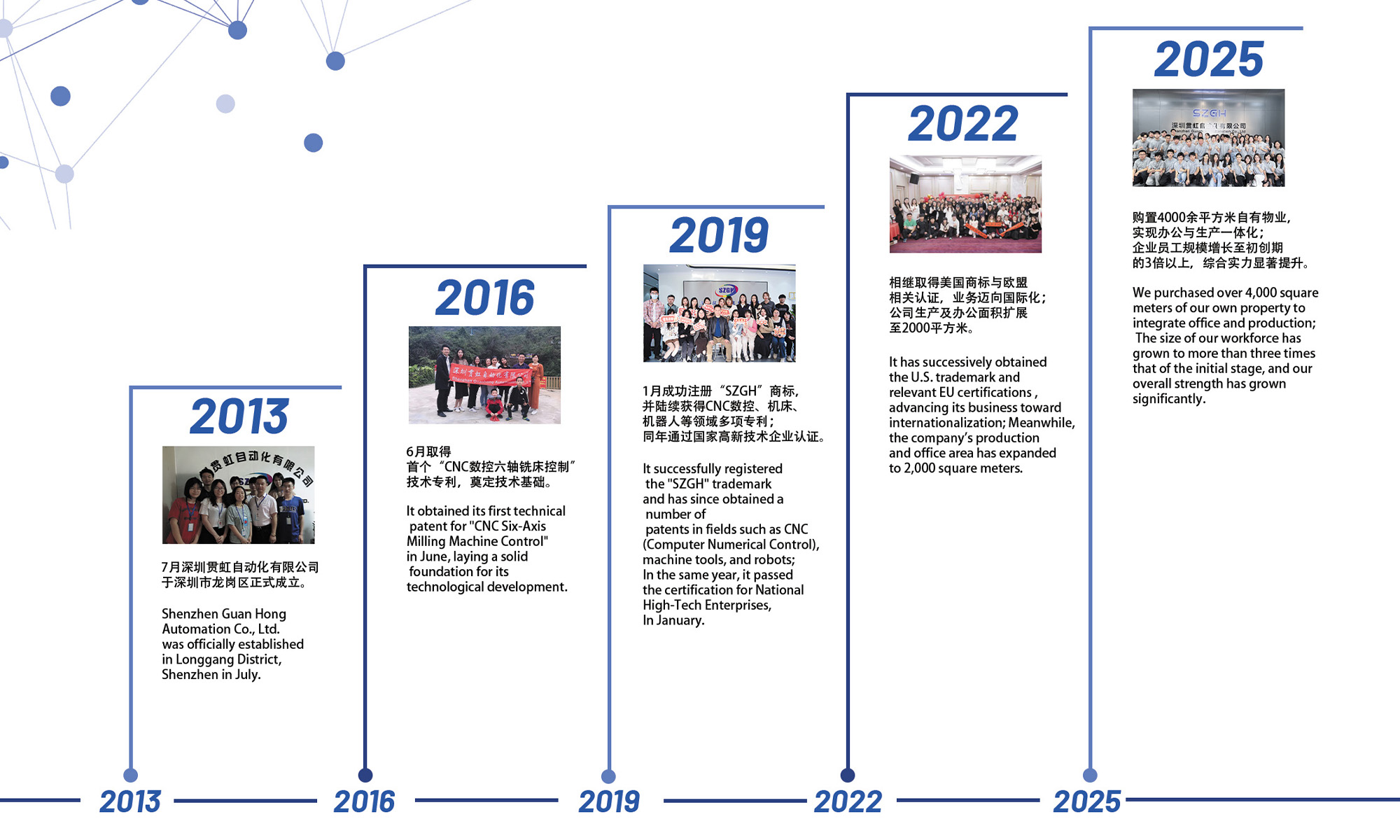

SZGHTECH – Growth Timeline & Factory Strength

2010 — On November 19, 2010, SZGHTECH Group was founded in Shenzhen, China. From its inception the company focused on CNC system R&D and automation.

2012 — On October 12, 2012, SZGHTECH obtained a utility-model patent for its first “four-axis CNC drilling & milling controller (GH series)”, marking the beginning of independent core-controller development.

2015 — On September 16, 2015, SZGHTECH was granted patents for a “multi-axis servo motor drive device” and a “control device for multi-axis combined CNC drilling/milling/boring machine tool.” That year, the company completed construction of a 20,000 ㎡ modern manufacturing base, establishing itself as a full-scale factory rather than a trading firm.

2016 — On July 20, 2016, the company expanded its R&D footprint by obtaining a utility-model patent for an “industrial welding robot,” signaling the start of robotic automation product lines.

2017 — By September 21, 2017, the robot factory was further expanded. By this time, SZGHTECH’s controllers and robot products were distributed across China and exported to India, Bangladesh, Nigeria, Vietnam, Turkey, Brazil, Indonesia, Mexico and other countries. On October 31, 2017, the company was officially recognized as a high-tech enterprise in China, reflecting strong R&D capabilities, complete hardware & software infrastructure, and rigorous quality management.

2018 — On March 15, 2018, after rigorous audit and on-site inspection, SZGHTECH successfully passed dual certification by Bureau Veritas (BV) and SGS (Gold Plus Supplier), further strengthening global customers’ trust in product quality and compliance.

2020–2022 — During this period, SZGHTECH strengthened ties with domestic trade and industry associations (e.g. visit by the local Science & Technology Finance Chamber of Commerce), and expanded company culture and team cohesion via internal events and performance competitions, demonstrating organizational stability and long-term growth orientation.

2023–2024 — SZGHTECH’s global sales and service footprint expanded to cover 80+ countries, backed by stable production capacity and reliable export logistics.

2025 — The company upgraded to a “smart factory” — improving motion-control algorithms, automation workflows, and production line intelligence, preparing for next-generation intelligent manufacturing demands. from a small CNC system developer to a large-scale factory with robotics and automation capabilities — but also demonstrates our long-term commitment to R&D, manufacturing scale, quality and global supply.

Full-scale 20,000 ㎡ manufacturing base — Since 2015 we’ve operated a large facility that houses CNC controller production, servo & motor assembly, CNC machine tool fabrication, robot assembly, and automation unit manufacturing — covering the full hardware + robotics + automation spectrum.

Self-developed core technologies & patents From early CNC controllers (2012) to multi-axis servo drives (2015) and welding robots (2016), SZGHTECH has maintained in-house R&D capabilities. This ensures we are not resellers — we own the intellectual property, control quality, and can customize solutions.

Certified quality & compliance Dual certification from Bureau Veritas and SGS in 2018 validates our manufacturing processes against international standards — critical for overseas buyers.

Large production capacity & global reach With a factory designed for high throughput and robust supply chain, SZGHTECH manufactures at scale — supporting exports to 80+ countries and delivering reliable, repeatable quality and timely deliveries.

Continual innovation & modernization The 2025 upgrade to a smart factory with advanced motion-control platforms shows long-term investment in automation, performance, and future-proofing.

Stable corporate structure & credibility Over 15 years of consistent growth, certifications, active participation in trade & industry associations, and global export history — give overseas clients confidence in SZGHTECH’s stability, legitimacy, and capability as a tech-forward manufacturer.

Our Partners

Always keep our promise, and always be responsible for our products.

First of all, thank you for your support and trust in us all the time. Because of you, SZGH goes further and further.

We believe that through our unremitting efforts and persistence, we will provide you with more professional, more detailed, more comprehensive, and more suitable high-quality services. Thank you for every trust you have placed in us, this is the source of strength and a strong pillar for us to keep moving forward!

May we help each other and grow together in the cause of CNC systems and industrial robots, leading to a better life and a better future.

Global Partners & Export Footprint

SZGHTECH’s CNC systems, industrial robots and automation machines are not only distributed across China — we export worldwide. Our export network includes partners and customers in countries and regions such as Turkey, Russia, Lebanon, North America (USA / Canada), Bolivia, Romania, Morocco, Egypt, Mexico, Moldova, among others.

As a manufacturer based in China, we benefit from China’s strong position in global CNC and machine-tool exports. According to export shipment data, China remains the top source country for CNC machines, with significant volumes shipped to markets including Turkey, Russia, and many other global destinations.

By working directly with factories like SZGHTECH — rather than intermediaries — our overseas partners enjoy stable supply, complete technical support, and genuine manufacturer-level warranties and quality control.

Our Factory

Our factory is located in Dongguan City, Guangdong Province, with an area of more than 20,000 square meters, five automated production lines, and more than 100 production employees to ensure product shipment and quality delivery

The factory workshop complies with the "6S Standard Management System": finishing, rectification, sweeping, cleanliness, quality, and safety. And strict quality control measures are implemented to ensure excellent reliability and high-standard quality.

Each product undergoes over 72 hours of testing by a professional quality inspection team before shipment, and undergoes a 100% inspection before packaging and shipment.

A dedicated robotics testing area is set up within the factory to thoroughly inspect all robotics orders and provide one-on-one confirmation with customers.

In addition, we will keep some inventory and set flexible delivery times to facilitate and better support your business.

Our Products

CNC Machine: CNC Lathe Machine,CNC Milling Machine Center,Vertical Machining Center,Inclined machine tools;

Industrial Robot Arm:Welding Robot Arm, Handling Robot Arm, Grinding Robot Arm, Painting/Spraying Robot Arm, Scara Robot Arm, General Robot Arm, Collaborative Robot;

CNC System Kit: Lathe CNC system, Milling CNC system, Plasma cutting CNC system, Grinding & router CNC system, Servo Motor & driver, Spindle servo motor & driver ;

Product Application

(1) Application of CNC system.

Multiple functions:It can realize the drilling/boring, roughing of round groove I rectangle groove, finishing of full circle/rectangle, continuous drilling of straight line/rectangle/arc, etc.

(2)Applications of Robotic Arms

Factory-Proven Robotic Solutions for Real Production Lines

At SZGHTECH, robotic arms are not designed for demonstrations — they are engineered, assembled, tested, and deployed for real factory environments.

From heavy-duty handling to precision welding and surface finishing, our robots are built to increase throughput, reduce labor dependency, and ensure consistent quality across industries.

Handling Robot Arm

Stable, High-Load Automation for Continuous Production

SZGH handling & palletizing robot arms are engineered for high-load, high-cycle industrial environments, especially where manual handling limits productivity or safety.

Typical Factory Applications

CNC machine tool loading & unloading

Material handling between machining, inspection, and packaging stations

Parts transfer in automated production lines

Palletizing & depalletizing for cartons, bags, metal components

Deburring support & rough cutting assistance

What Factory Buyers Care About — And We Deliver

High payload & long reach: Designed for stable operation with heavy parts and extended work envelopes

24/7 reliability: Industrial-grade motors, reducers, and control systems tested for continuous shifts

Seamless integration: Compatible with CNC machines, conveyors, AGVs, and MES systems

Lower labor dependency: One robot replaces repetitive manual handling across multiple stations

Ideal for machine tool factories, metal processing plants, logistics lines, and automated workshops

Grinding Robot Arm

Consistent Surface Quality Without Manual Fatigue

SZGH spraying robot arms deliver highly uniform coating results, designed for environments where appearance quality, coating thickness, and material efficiency matter.

Application Fields

General industrial spraying

Automotive painting & coating lines

3C electronics spraying

Furniture and wood product finishing

Bathroom hardware coating

Aerospace components & yacht surface treatment

What Sets Our Spraying Robots Apart?

Stable spray paths for even thickness and finish

Reduced paint waste through precise motion control

Cleaner production environments with enclosed robot spraying cells

Scalable systems from single robot to full painting lines

Ideal for manufacturers pursuing high appearance standards, cost control, and environmental compliance.

Welding Robot Arm

High-Precision Welding Built for Mass Production

SZGH welding robot arms are built for high-accuracy, high-repeatability welding tasks, ensuring consistent weld quality even in demanding industrial environments.

Supported Welding Processes

MIG / MAG welding

CO₂ welding

Laser welding (optional configurations)

Industries We Serve

Construction machinery manufacturing

Automotive and auto parts production

Electronic equipment enclosures

Shipbuilding and steel structures

Metal doors, windows, and furniture manufacturing

Factory-Level Advantages

Consistent weld penetration & bead quality across long production runs

Reduced scrap & post-weld correction

High-speed motion control for takt-time-sensitive lines

Flexible programming for multi-model, small-batch, or mass production

Trusted by factories seeking stable weld quality, scalable automation, and reduced reliance on skilled welders

Spraying Robot Arm

Uniform Coating Quality with Reduced Material Waste

SZGH spraying robot arms deliver highly uniform coating results, designed for environments where appearance quality, coating thickness, and material efficiency matter.

Application Fields

General industrial spraying

Automotive painting & coating lines

3C electronics spraying

Furniture and wood product finishing

Bathroom hardware coating

Aerospace components & yacht surface treatment

What Sets Our Spraying Robots Apart?

Stable spray paths for even thickness and finish

Reduced paint wastethrough precise motion control

Cleaner production environments with enclosed robot spraying cells

Scalable systems from single robot to full painting lines

Ideal for manufacturers pursuing high appearance standards, cost control, and environmental compliance.

Why Factories Choose SZGHTECH Robotic Arms?

Real Manufacturer: Robots are developed, assembled, and tested in-house

Industrial-Grade Design: Built for dust, vibration, and continuous operation

Customization Capability: Payload, reach, tooling, and software tailored to your production

Export-Ready Delivery: Global shipping, documentation, and technical support

Looking to automate handling, welding, grinding, or spraying in your factory?

Contact SZGHTECH to receive a production-ready robotic solution — engineered for your real workload, not just specifications.

Our Certificate

SZGHTECH runs a full-scale 20,000 ㎡ factory where all operations — from in-house R&D, servo & motion-control development, CNC controller and robot production, to final quality inspection — are strictly managed under one roof. We hold recognized factory-level certifications from Bureau Veritas (BV) and SGS (Gold Plus Supplier Assessment), ensuring our manufacturing, QC, and export processes meet rigorous global standards. Our machines are CE-marked, fully compliant with EU safety, electrical, and environmental regulations — ready for lawful sale and operation across Europe and the entire EEA.

As a direct manufacturer (not a trading agent), SZGHTECH provides complete documentation — technical files, CE declarations, export-ready paperwork, user manuals — along with traceable production records and export-ready CNC & robotic automation systems.

Choosing SZGHTECH means partnering with a globally certified, export-ready manufacturer, delivering high-precision, compliant automation solutions — ready for installation and reliable operation anywhere in the world.

Production Market

We have a large number of customers across Asia, America, the Middle East, Europe, South America, and Africa. Specially we already built own business corporate group in Middle East market.

Secondly, we have our own agents in Egypt, Iran, Russia, Turkey, Morocco and other countries.

Finally, SZGH is also gradually expanding our CNC systems and robot arms market. Especially in the robot arm market, under the current situation, automated production will be a major trend.

The following figure is the certificate authorized by the agent:

Our Service

Certified actual products - We have a zero-tolerance policy for asset recovery vendors.

Lowest package prices -Always offer lower prices than other companies.

Professional technical engineer team- possible fastest response and support to client's application demand.

Professional overseas sales team---Respond to customer needs in a timely manner, provide 24-hour online service, and solve practical problems for customers from the perspective of customers.

Quality guarantee – Free, one-year warranty and life-long maintenance. For any quality problem, GuanHong promises to refund.

Fast, professional, and reliable International delivery – flexible and low-cost delivery solution for clients.